Harness the power of fleet data to lower your total cost of operation

Harness the power of fleet data to lower your total cost of operation

09/04/2021

How telematics can boost your materials handling operation

Would you like to manage your lift truck fleet in a way that saves money, raises productivity, improves health and safety, and lowers environmental impacts? That’s the promise of telematics. With help from experts on the subject, Mark Nicholson explains how your business can benefit from this data-driven management approach.

Finnish Cat® lift truck distributor Logisnext Finland is a specialist in the development and application of telematics and other digitally based services. “A manager can’t physically watch a forklift’s activities 24 hours a day, or see what’s happening under its skin,” says Outi Kettunen, the company’s Director of Business Development and Sustainability. “The larger the fleet, the more difficult it becomes to keep an eye on every truck. Our answer is to monitor everything remotely, using a telematics system. This technology gives managers all the information they need to run their fleets more efficiently and effectively.”

It tells them, for instance, where each truck is; who is driving it; what it’s doing (and what has been done to it!); how its components are performing, and what is their condition. These parameters can be observed in near real time, and the data collected builds up into a comprehensive history which is analysed to see where improvements are needed.

“When combined with information from other sources, like ERP (enterprise resource planning) systems and service records, that data becomes even more powerful,” Outi adds.

If you’re wondering whether your fleet is large enough to benefit fully from telematics, she has this advice: “Usually the benefits arise when there are at least 10 trucks, and preferably 30 or more. However, telematics also has uses in some smaller fleets; for example, where lift trucks are crucial in keeping production running and where downtime would be very expensive. It can be applied to all units, from the smallest power pallet truck to the biggest electric or IC engine counterbalance forklift.”

How telematics works

Telematics is one of today’s expanding applications of the Internet of Things (IoT), which enables objects (in this case trucks and their components) to send and receive information. IoT devices fitted to the truck provide location, sensing and diagnostic connection functions, as well as storage and transmission of data. They send their information to a cloud-based server via wireless networks like WiFi, 3G, 4G, 5G and satellite. There it is processed, analysed, interpreted and displayed, via the internet, on users’ desktop, laptop, tablet or phone screens.

Telematics technology gives managers all the information they need to run their fleets more efficiently and effectively.

What telematics can monitor

Depending on the system and contract specifications,

you can monitor all this and more:

- Driver identity

- Truck position

- Truck activity including active and inactive time; starts and stops; idling time during tasks; time spent on specific movements, e.g. travelling, lifting, lowering and tilting; daily and seasonal patterns of use

- Driving characteristics such as speed, harsh acceleration and braking, and fast cornering

- Shocks – both large and small

- Engine and motor data including odometer readings, fuel or electricity consumption, temperatures and faults

- Battery data including temperature, electrolyte level, state of charge, and charging and discharging history; on Li-ion batteries, data can be drawn from the battery’s own BMS (battery management system)

- Completion of pre-shift checks

“Importantly, all of this should be joined up with data on the fleet and its servicing, including contracts, serial numbers, truck details and accessories, as well as service history and costs,” Outi Kettunen emphasises. “This is our starting point for making connections between problems and causes, and taking well-informed decisions.”

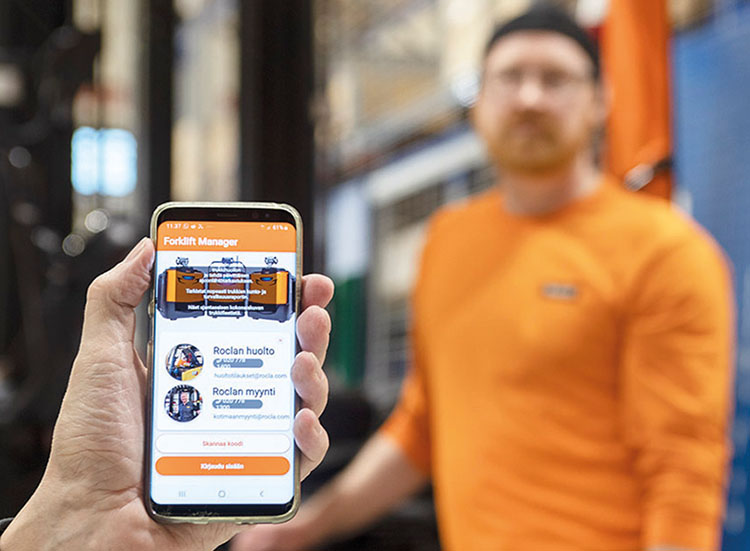

Logisnext Finland’s telematics solutions include different mobile apps tailored to the needs of customers, managers and technicians.

Telematics’ key benefits

Here are some of the improvements telematics will allow you to make:

- Lower total cost of operation (TCO). Enforce daily checks. Deal with faults quickly, before damage develops. Schedule repairs and preventative maintenance to minimise downtime. Identify causes of excessive wear or premature failure in components. Maintain truck condition to maximise performance, efficiency and service life.

- Fleet streamlining. Gain a clear overview of operations. Remove unnecessary trucks. Reassign and fully utilise under-used trucks. Change the mix of truck types if some are in roles better served by a different category.

- Easier administration. Make contract conditions, cost responsibilities, hours worked and other relevant details transparent to both supplier and user. Enable fair, trusting, positive collaboration and fruitful partnership. Be certain of truck and battery condition when the time comes to resell or reuse.

- Lower fuel and energy costs. Encourage efficient driving behaviour. Identify and remove traffic bottlenecks and other reasons for idling.

- Optimum battery use. Ensure charging at the right times and levels. Extend battery lifetime.

- Fewer accidents. Allow only authorised drivers to use trucks. Assess driving behaviour. Reward those with good habits and provide specific additional training for those who need it. Investigate accidents to identify and remedy causes, hazards and danger areas, and make drivers accountable if they are at fault.

- Improved employee safety and satisfaction. Reward good drivers. Improve working conditions. Identify any links between patterns of behaviour or truck use and illnesses such as repetitive strain injury.

Optimum scheduling of maintenance maximises uptime and performance.

Juha Pöllänen, Director of ICT and Parts Operations at Logisnext Finland, summarises the value of these gains. “Telematics boosts productivity by ensuring you have right truck in the right place at the right time; each one maintained to give high performance and uptime, and driven well by operators who have received targeted training and encouragement. Costs are reduced by streamlining fleet size, by cutting fuel and electricity bills, and by extending the life of batteries and other components so fewer replacements are needed. There is also less expense relating to damaged trucks, workplace structures and goods, as well as injury, illness and sickness absence.

“Better sustainability is an additional bonus. More efficient use of fuel and power means lower CO2 emissions, while reduced accident damage and longer component life helps conserve the earth’s material resources and avoids the energy and emissions associated with frequent repair and replacement of broken or worn items.”

Telematics ensures that every truck, of every type and size, is in the right place at the right time.

Connecting data

“To give an idea of how working with telematics and other data leads to improvements, here are just a couple of examples. In one case, frequent tyre replacement was previously costing more than the customer’s hire fee. Telematics indicated many upward shocks, from which we concluded that a poor workplace floor was wearing tyres rapidly and needed attention. Another customer cut collisions by 90% through identifying the drivers involved and rewarding good driving.”

Outi Kettunen, Director of Business Development and Sustainability, Logisnext Finland

Outi Kettunen, Director of Business Development and Sustainability, Logisnext Finland

Telematics and the future

“We expect telematics technology to continue growing in sophistication, versatility and affordability. Developments are likely to include more precise indoor location and tracking, more intuitive user interfaces and displays of information, and more extensive connection with other data sources. For instance, linking to human resources and training systems could allow automatic verification of an operator’s suitability to drive a particular truck. Artificial intelligence and machine learning will bring further possibilities, such as autonomous decision-making and interaction with automated systems and cobots.

“We see telematics data as an essential ‘fuel’ for effective intralogistics, now and in the future. You could say data is like oil – and we would add that data is in some ways renewable and reusable for different value creation purposes. Its importance in decision-making at all levels is increasing rapidly, and the insights and understanding it makes possible are sure to add value for organisations and societies. To fulfil that potential, there will be a need for more data engineers and data scientists. At Logisnext Finland we are already more than a decade into our own data journey, and we look forward to achieving even greater heights with our customers.”

Juha Pöllänen, Director, ICT and Parts Operations, Logisnext Finland

Juha Pöllänen, Director, ICT and Parts Operations, Logisnext Finland

Telematics for you

The telematics solution described is offered by Logisnext Finland to customers in that country. Outside Finland, you can contact your local Cat® lift truck dealer for advice on suitable systems and providers.

To find out more about what telematics involves and how it can be applied to your fleet, your lift truck supplier is a good initial source of information. Juha suggests you consider the following issues.

“Telematics is available as a service. You will pay a monthly fee for a complete package including the IoT devices, user interfaces, data processing and essential analytics. Check that your telematics agreement covers everything you need, that you are not paying for anything you won’t use, and that all costs are transparent. Our optional extras, for example, include a battery management system. We are also developing additional analytics services.

“Make sure the user interfaces and information displayed are easy to use and interpret by staff at all levels in your company, and that actions can be taken as a result. To gain maximum benefit from the data generated, you will need to be able to call on the telematics provider’s analytics expertise and guidance in major decision-making. Look for providers and equipment with a reputation for reliability and data security. Finally, ask for evidence that the systems will be scalable to match with your growing needs, adaptable to link with other current and future data sources, and futureproofed to benefit from continuing developments in technology and functionality.”

Source : https://eurekapub.eu/fleet-management/2021/03/30/harness-the-power-of-fleet-data-to-lower-your-total-cost-of-operation-tco