Think before you tick

29/09/2020

Lift truck daily checks

When carrying out a lift truck’s daily or pre-shift checks, what are you actually looking for? Mark Nicholson suggests you answer the following questions before ticking boxes on your checklist.

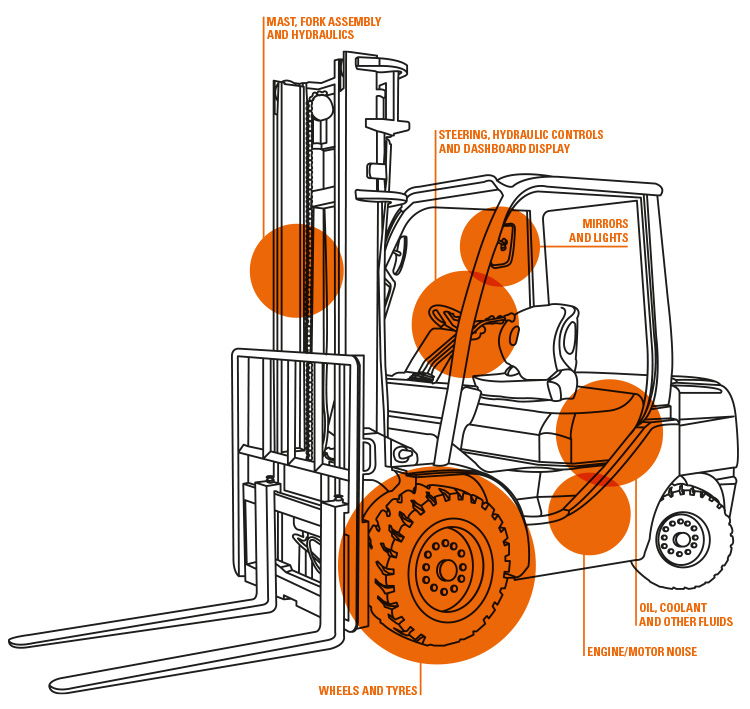

Before starting the motor or engine

YESTERDAY’S CHECKS

Have all faults noted on the previous day or shift been dealt with?WALKAROUND INSPECTION

Leaks

Can you see any liquid on the floor, under or near to the truck?Hydraulic fluid level*

Does it need topping up?Hydraulic hoses

Are they in good condition? Is there any leaked fluid on them?Mast and fork carriage

Do any of the structures look worn, cracked, bent or otherwise damaged? Can you see traces of wall plaster or paint, suggesting they have been in a collision? Are they very rusty? Are there any loose or missing bolts or fixtures, particularly where the mast is attached to the chassis and the tilting mechanism? Are moving parts – including bearing surfaces – contaminated with materials like mud or cement, and are they well lubricated? Are there leaks from the hydraulic cylinders?Chains and fixing bolts

Do any of the chain links seem stretched or damaged? Are the chains very rusty? Are they well lubricated? Do the fixing bolts show any sign of damage?Forks

Can you find any cracks or other signs of damage, especially at the heels? Are the forks bent, dented or excessively worn? Are they firmly attached? Are the pins, hooks or other attaching features in good condition?Load backrest extension

Is it bent, dented, cracked or loose? Is there anything caught up in the structure, like a piece of brick or block?Mast attachments (if present)

Are they securely attached? Are the fixing or locking points, hydraulic hoses and other connections in good condition?Wheels and tyres

Do the tyres have enough tread? Is there any sign of damage, including cracks, cuts, tears, bulges, or nails and other embedded objects, in the tread surface or side walls? In the case of pneumatic tyres, is the air pressure* correct? Are the wheels and especially their rims damaged? Are the wheel nuts tightly fastened?Steering linkage

Is it well lubricated?Truck body and overhead guard

Are any of the bodywork panels or overhead guard structures damaged?Safety guards and covers

Are they securely attached and fastened?Windows and other transparent panels

Is there any obstruction to visibility? Are there cracks, tears or scratches? Is vision reduced by stickers? Is dirt making the view unclear? Is paint, cement or any other hard-to-remove substance sticking to the surfaces?Mirrors

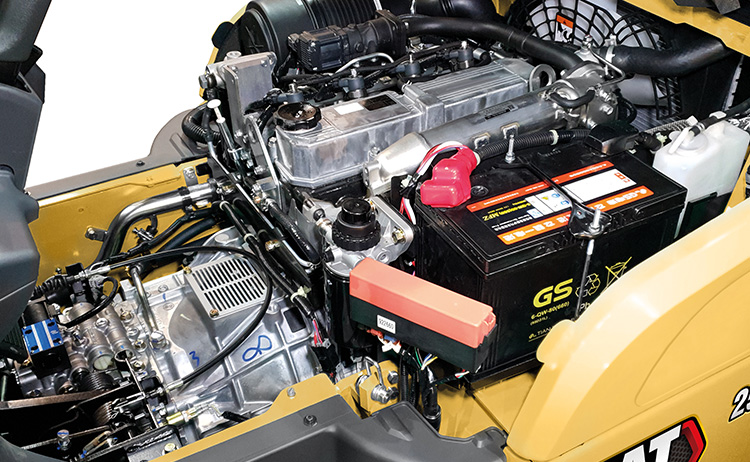

Are they cracked? Are they clean? Do they give a clear reflected view?IC ENGINE TRUCK CHECKS

Fuel, engine oil and coolant levels*

Do they need topping up?LPG bottle

Are its clamps and gas line connections secure?AdBlue or other additives*

If these are used (as in some diesel engines), do they need topping up?Battery

Is it securely attached? Is it clean? Are there any signs of leakage? Does it need topping up with distilled water? (NB top-ups are not needed for Li-ion or sealed lead-acid batteries.)Fan and other belts

Are they worn, damaged or loose?ELECTRIC-POWERED TRUCK CHECKS

Battery charge level

Has the battery been charged sufficiently for the shift or will it need replacing?Battery electrolyte*

Do any of the cells need topping up with distilled water? Is the electrolyte’s specific gravity within the correct range? (NB these checks are not needed for Li-ion or sealed lead-acid batteries.)Battery cables and connections

Are they clean, in good condition and secure?Battery general condition

Is it clean? Are there any signs of leakage?Battery security

Is it firmly held in place, with its locking device (if present) activated? Is the battery compartment securely closed?

Battery.

Daily checks are an important defence against accidents arising from operating a lift truck in unsafe condition.

Onboard checks

OPERATOR AREA

Steps and cabin floor

Is your workspace clear of rubbish and other potential slipping or tripping hazards?Seat and seat belt

Is the seat firmly fixed to the truck, with no loose movement? Is the seat belt securely attached and can it be fastened and adjusted?MONITORING, CONTROL AND SAFETY SYSTEMS

Operating system

After switching on, does the computerised display (if present) go through its normal initialisation sequence? Is there any fault indication?Dashboard warning lights

Have any of the warning lights stayed on?Gauges and instruments

Are they showing appropriate readings?Working lights and beacons

Are all lights functioning?Other warning systems

Does the horn work? Does the reversing alarm (if present) sound when reverse is selected? Are there warning lights and/or audible alarms linked to use of parking brakes, seat belts etc., and are they working?OPERATOR CONTROLS

Steering

Does the steering feel normal and turn smoothly from lock to lock? Is there any unexpected movement or looseness?Hydraulics

Do all of the hydraulic functions – including lift, lower, tilt and (if present) sideshift or other attachments – operate as expected? Does the mast move without any twisting, sticking or juddering?Pedals

Driving over a short distance to test them, do the foot-operated controls (including the inching pedal on an IC engine truck) work normally?Parking brake

Testing on a slight slope if possible, does it hold the truck firmly and release correctly?Service brakes

Do they bring the truck to a stop effectively and do they feel normal?Noises

Are you hearing any unusual sounds from the electric motors, engine or other systems?

Parking brake.

Service brake and other pedal controls.

Horn and other warning systems.

What to do next

If you have found a fault, you should report it immediately to the relevant manager. He or she will decide whether it is safe to carry on using the lift truck or if it should be taken out of service. An effective system for fixing problems identified by daily checks is essential.Skipping daily checks, or carrying them out incompletely, is a false economy that can lead to accidents, breakdowns, high repair bills and a shorter truck life.

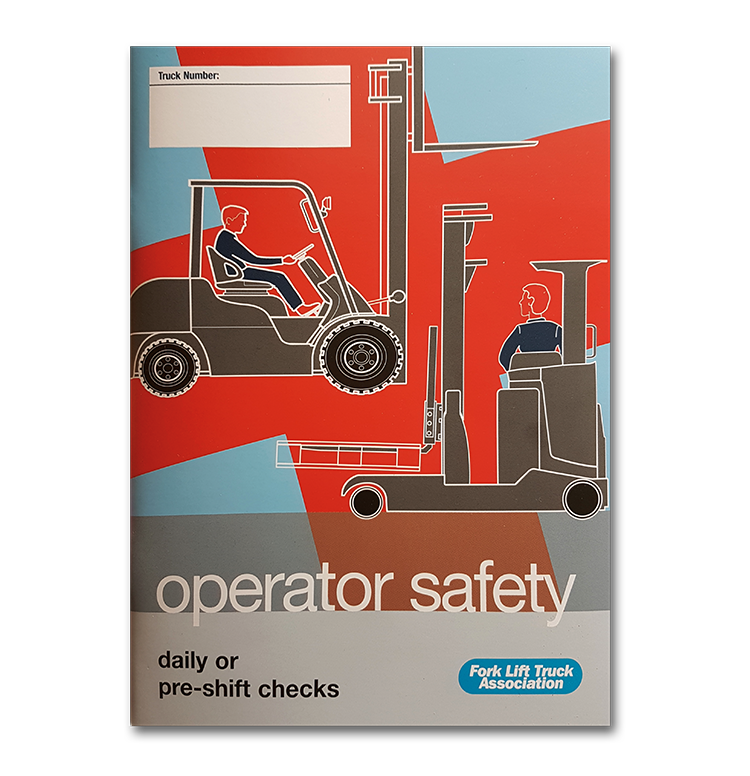

Ready-made checklists

Your lift truck supplier may provide a checklist to copy, or your company may create its own check sheets tailored to the trucks used. Various organisations produce generalised checklists. A good example is the booklet “Operator Safety – Daily or Pre-shift Checks” from the UK Fork Lift Truck Association (FLTA). This gives advice on the checking process and contains 66 copies of the checklist form, so that records for a truck can easily be kept together. Visit the ‘Store’ at www.fork-truck.org.uk for more details.

Digital daily checks

Software developer CheckedSafe offers a mobile app allowing standard FLTA daily checks to be carried out via your phone or tablet. The form is completed on-screen and photographs of defects can be taken and saved with it. As well as saving time and paper, it makes transmission of reports instant. The relevant manager is automatically alerted to problems, and the system enables efficient management of remedial actions. A complete audit trail for the truck is maintained, including motion detection records which confirm that all items have been properly checked and not just ticked without looking. CheckedSafe can supply the app in languages other than English

Beware of false economy

Skipping daily checks, or carrying them out incompletely, is a false economy that can lead to accidents, breakdowns, high repair bills and a shorter truck life. Time efficiency can, however, be gained by design features which give quick and easy access to items that need checking. Li-ion batteries, requiring virtually no maintenance, are another time-saving option. These advantages are available in the lift truck product range from Cat® Lift Trucks

Source : https://eurekapub.eu/health-safety/2020/09/24/think-before-you-tick